Our Work

This page highlights a selection of projects where we’ve helped our clients transform ideas into tangible results. From early hand sketches and rough concepts to detailed 3D designs, functional prototypes, and finished 3D-printed parts, our work bridges the gap between imagination and manufacture. Each example showcases our approach to design for additive manufacturing, rapid prototyping, and problem-solving—turning concepts into accurate, testable, and production-ready components.

Adamo Foods

Case Study: Creating a Custom Press to Shape a Realistic Fungi-Based Steak

Client Background

Our client, a visionary founder in the plant-based food industry, approached us with an innovative challenge. His company specialises in crafting high-quality plant-based meat alternatives, and he wanted to take his flagship product—a fungi-based “steak”—to the next level. While the flavour and texture were already excellent, he needed a solution to achieve a consistent, realistic steak shape that would cook, slice, and present like traditional meat.

The Challenge

The client needed a custom device—a press—that could:

-

Hold and compress the fungi-based mixture

-

Remove excess liquid without damaging the structure

-

Create a uniform, cohesive block

-

Shape the product so it could be cooked and sliced like a real steak

The design had to be food-safe, easy to operate, reusable, and capable of producing consistent results at small-batch production scale.

Our Approach

We began with a deep discovery session to understand the texture, moisture levels, and behaviour of the fungi-based mixture during cooking. From there, we developed a series of concepts focusing on three key areas:

-

Drainage efficiency — ensuring the press expelled unnecessary liquid while maintaining internal structure

-

Uniform shaping — creating repeatable steak-like forms

-

Durability & usability — making the press robust yet simple to use in a production kitchen

Through prototyping and iterative testing with the client’s actual product, we refined the shape, internal channels, and compression mechanics to ensure an even press every time.

The Solution

The final outcome was a custom-engineered press featuring:

-

A precision-shaped mold that forms the fungi mixture into a realistic steak outline

-

Integrated drainage slots placed strategically to remove moisture without compromising density

-

A reinforced compression plate ensuring even pressure from top to bottom

-

Food-safe materials built for durability and easy sanitisation

-

A modular design so the client can scale production with additional units

Once the mixture is added and compressed, the press releases the product as a single cohesive piece—ready to cook, sear, and slice just like traditional steak.

Results

With the new press, the client can now produce:

-

Perfectly shaped, uniform steaks

-

Enhanced texture and structure thanks to controlled liquid removal

-

Consistent batch-to-batch quality

-

A product that cooks and cuts like real steak, improving consumer experience and market appeal

This custom solution has helped the client elevate his product line, increase production efficiency, and strengthen his brand presence in the rapidly growing vegetarian food market.

Rainpod

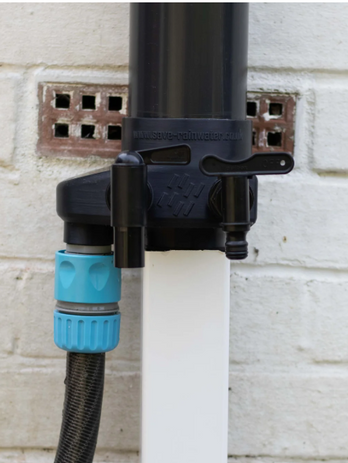

Case Study: Bringing a Smarter, Space-Saving Water Butt From Idea to Reality

Client Vision

Our client approached us with a simple but ambitious idea:

Create a discreet, space-efficient water butt that would collect rainwater effortlessly, reduce household water bills, and blend seamlessly into any garden.

They had the concept — but needed a partner to refine the design, validate feasibility, and take it from a sketch on paper to a market-ready product.

The Challenge

Traditional water butts are bulky, unattractive, and often awkward to position. The client wanted to solve all three issues at once:

-

A compact and discreet form that wouldn’t dominate small garden spaces

-

Hands-free rainwater collection, with minimal setup

-

A design that saves users money by reusing collected rainwater

-

A solution that was easy to manufacture, durable, and user-friendly

Our task was to turn these ambitions into a product that delivered both style and functionality.

Our Approach

We began with a deep-dive discovery session to understand the client’s goals, usage scenarios, and target customers. From there, we developed a structured plan:

1. Concept Refinement

We transformed the client’s initial idea into a clear product direction, exploring shape, size, placement options, and usability features. Early sketches and mock-ups helped define the most space-efficient configuration.

2. Functional Design + Engineering

Next, we engineered a system that channelled rainwater automatically, requiring minimal user intervention. We selected durable materials, integrated discreet overflow and filtration elements, and ensured the design was compatible with typical downpipes and garden layouts.

3. Prototyping & Testing

We produced high-fidelity prototypes to test functionality, water flow, structural integrity, and overall appearance. User feedback helped refine the final shape and usability features.

4. Preparing for Manufacture

Once validated, we produced detailed CAD, technical drawings, and specifications ready for full-scale production. The result was a design that is cost-effective to manufacture and built to last.

The Result

The final product is a sleek, discreet water butt that fits neatly against a wall or fence, blending effortlessly into its surroundings. It collects rainwater automatically, giving homeowners an easy, sustainable way to reduce their water usage — without sacrificing garden space or aesthetics.

The client now has a fully realised product ready for market launch, with a compelling story rooted in sustainability, innovation, and smart design.

Outcome

-

A fully engineered, market-ready product derived from an initial idea

-

A space-saving, visually appealing solution designed for modern gardens

-

A sustainable product that helps homeowners cut down on water bills

-

A strong foundation for branding, marketing, and future product line expansion

-

You can see our product in action at www.save-rainwater.co.uk